History

Unger Fabrikker A.S is one of Europe’s leading producers of anionic surfactants, and the only one of it’s kind in Scandinavia. Take a look below to understand why we are where we are today.

1922

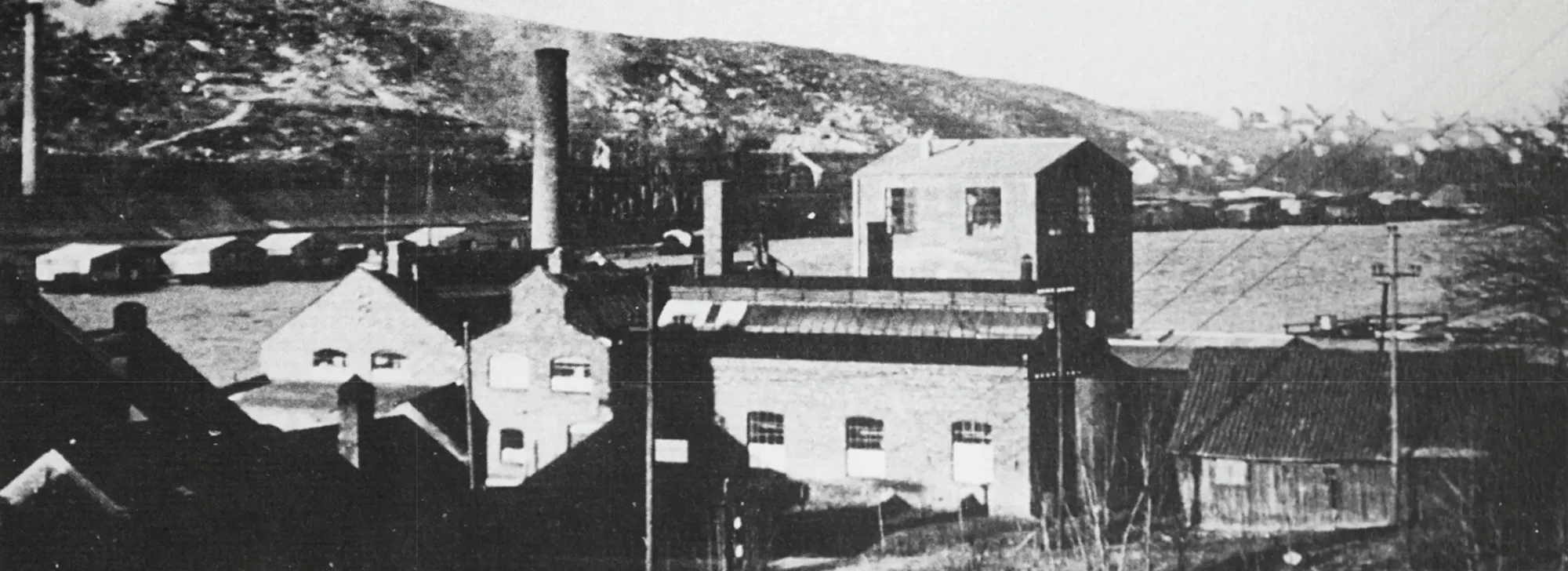

A/S Fredriksstad Saapefabrik is founded

Engineer Theodor Broch Unger founds A/S Fredriksstad Saapefabrik on 19th June 1922.Unger's aim was to supply 20% of Østfold's population with soft soap, washing powder and scouring powder.

1922

1920's – early 30's

1920's – early 30's

Growth in troubling times

The 20's and early 30’s were perhaps the most difficult period Norwegian industry has ever faced. As prices and wages sank, strikes and lock-outs threatened to bring industry to a standstill. Fredriksstad Saapefabrik escaped serious conflicts, but instability in the labour market affected both production and sales. When Fredriksstad Privatbank itself went bankrupt in 1924 it became increasingly difficult to get credit. In fact, on a couple of occasions T. B. Unger had to use his children’s bank accounts as security for loans. However, T. B. Unger ignored advice that he should give up.

Fredriksstad Saapefabrik grew in spite of these problems. In its first year the work force grew from 7-8 to 20 and its products were sold nationwide. Foremost among these was the soapflake Skinn-hvitt which was highly recommended by both schools of home economics and textile factories.

Jarl, the cheapest soap powder on the market, and the soft soap Vegetal, were two other products that sold well.

T. B. Unger was quick to realize the need to invest in active marketing. During the worst years of the Depression advertisements often emphasized the patriotic duty to “buy Norwegian goods”. There was also a noticeable penchant for rhyming jingles - like this one from the launch of the new Sonora toilet soap: «In fashion you are sure to win, with beautiful Sonora skin!»

Fredriksstad Saapefabrik grew in spite of these problems. In its first year the work force grew from 7-8 to 20 and its products were sold nationwide. Foremost among these was the soapflake Skinn-hvitt which was highly recommended by both schools of home economics and textile factories.

Jarl, the cheapest soap powder on the market, and the soft soap Vegetal, were two other products that sold well.

T. B. Unger was quick to realize the need to invest in active marketing. During the worst years of the Depression advertisements often emphasized the patriotic duty to “buy Norwegian goods”. There was also a noticeable penchant for rhyming jingles - like this one from the launch of the new Sonora toilet soap: «In fashion you are sure to win, with beautiful Sonora skin!»

1939 – 1945

The war

By 1939 Fredriksstad Saapefabrik was economically viable and marketing 26 products and 54 raw materials. The detergent industry was relatively unaffected by the German occupation during the war, although Fredriksstad Saapefabrik did suffer an explosion in 1942 in which a new three-story building was destroyed. Later that year T. B. Unger’s three companies were merged with Unger himself as sole owner. In the last years of the war he, along with 1100 other Norwegian officers, was arrested by the Nazis and sent to Germany. In his absence sales manager Einar Moe took com-???

1939 – 1945

1945–1947

1945–1947

Post war years

Rationing and a decline in consumption led to difficulties in the post-war period, and in autumn 1945 Unger Fabrikker experienced the only strike in its history - lasting 3 1/2 hours and resolved when dismissed workers were reinstated. However, by 1947 Norwegian industry was back to 1937 production levels and continued to grow, with oil and fats-based industries among those leading the field.

Early 50's

Backing out of soap

For a period after the war Unger Fabrikker was the third largest soap manufacturer in Norway, with 110 employees and approx. 8000 merchant customers nationwide. But as the economy grew, so too did international competition. Reluctantly T.B. Unger decided that soap production should be phased out at the plant and the production equipment sold at a fair profit to other struggling Norwegian soap manufacturers.

The end of soap production led to job losses, but fortunately at a time when other employment was easy to find. T.B. Unger believed that the future lay in synthetic detergents, while the production of auxiliaries for the textile industry, which in the 50’s was enjoying a resurgence, would provide the best profits in the transition period.

The end of soap production led to job losses, but fortunately at a time when other employment was easy to find. T.B. Unger believed that the future lay in synthetic detergents, while the production of auxiliaries for the textile industry, which in the 50’s was enjoying a resurgence, would provide the best profits in the transition period.

Early 50's

1953 – 1958

1953 – 1958

Turning the tide?

It is a token of the difficulties the company was facing at this time that sales in the beginning of the 1950's had declined compared to the late 40’s. However, fortunes turned in 1953, otherwise a difficult year for a Norwegian industry increasingly beset by competition. Sales figures for the company’s 70 products show a remarkable growth until the next lean year, in 1958.

1953 – 1958

The not (yet) to be merger

In 1958 Unger Fabrikker had a work force of 43, of which 23 were involved in production, working two shifts every day except Saturday and Sunday. The company’s range of products was under constant reassessment, reflecting T. B. Unger’s emphasis on laboratory work as a guarantee of technical development and dynamism.

With falling profit margins the Norwegian chemical industry found itself hard pressed at the end of the 50’s. Added to this was the uncertainty created by the establishment of the EEC and EFTA. Mergers seemed the order of the day, and in 1958 Unger Fabrikker and Borregaard started discussions on technical and commercial cooperation with a view to a possible merger. The merger, however, was not yet to be.

T. B. Unger’s own unwillingness to “sell his own child” was undoubtedly a reason why merger plans were never realized. However, it was decided that Unger Fabrikker should again become a private limited company, with a total share capital of kr.200.000 divided between 400 shares. Since T.B. Unger himself owned all the shares but two, there was little practical change.

With falling profit margins the Norwegian chemical industry found itself hard pressed at the end of the 50’s. Added to this was the uncertainty created by the establishment of the EEC and EFTA. Mergers seemed the order of the day, and in 1958 Unger Fabrikker and Borregaard started discussions on technical and commercial cooperation with a view to a possible merger. The merger, however, was not yet to be.

T. B. Unger’s own unwillingness to “sell his own child” was undoubtedly a reason why merger plans were never realized. However, it was decided that Unger Fabrikker should again become a private limited company, with a total share capital of kr.200.000 divided between 400 shares. Since T.B. Unger himself owned all the shares but two, there was little practical change.

1953 – 1958

1960's

1960's

Continuous growth

The 60's was a period of continued growth and development. Works engineer Eilertsen drew up plans for a fully automated plant for the production of SO3 gas for the the sulphonation of alkylates. The plant was put into operation in 1963 and further extended with a larger one a year later. In 1965 a 10-acre lot was purchased in Selbak and became the site of a new factory for the production of alkylaryl sulphonates in powder form. However, plans for chemical production at a newly acquired site on Glomma’s western bank were not realized.

962 – 1968

Rising exports

As production and sales increased, so too did exports, rising from 40% to 80% of total sales between 1962 and 1968. Sulphonation was a key to opening up markets, first in Scandinavia, where Unger Fabrikker had long been established, and later in West Germany. The Selbak plant was built specifically with the Eastern European market in mind. Contacts with the Middle East were complicated by political upheavels, while some progress was made in Latin America.

962 – 1968

1968 – 1969

1968 – 1969

Active retirement

Share capital was increased to kr.1,500,000 in 1968. 2/3 of 1500 shares were now held by T. B. Unger’s children and grandchildren, the rest by T. B. Unger himself. When he retired in 1969, little changed. Son-in-law Rolf Kilde took over as managing director, but T. B. Unger continued to be as active as ever, serving alternate years with Kilde as board chairman, and functioning as managing director again for a year in 1977.

1970's

On the offensive

Unger Fabrikker’s investments in the 70’s show a company on the offensive. A new SO3 plant and a new sulphonation and neutralization plant was ordered from Meccaniche Moderne in Italy, to be delivered in 1975. In 1974 Fredrikstad Tremzlfabrik A/S was bought up to make way for a new plant at Nabbetorp for the production of synthetic raw materials. Unger Fabrikker was now one of the largest companies in Europe in its field.

Although the 70’s were a positive period for the company, profits were often variable as a result of world events. Norway's “no” vote to EEC membership, the oil crisis in 1973 and the Iran-Iraq war in 1980, were just some of the events that, directly or indirectly, affected sales. New markets were opened up in the Far East, Africa and the West Indies, but at the same time important customers in Poland and Czechoslovakia were lost.

Although the 70’s were a positive period for the company, profits were often variable as a result of world events. Norway's “no” vote to EEC membership, the oil crisis in 1973 and the Iran-Iraq war in 1980, were just some of the events that, directly or indirectly, affected sales. New markets were opened up in the Far East, Africa and the West Indies, but at the same time important customers in Poland and Czechoslovakia were lost.

1970's

1980–1982

1980–1982

Ups and downs

By 1980 91,4% of Unger Fabrikker’s sales were exports to customers in some 45 countries. It was primarily the rising price of oil and electricity that led to a 45% jump in energy costs. Sales and gradually also production increased by 14% in 1981. The labour force was increased from 99 to 106, but upheavels in the Middle East led to 15 employees being laid off in 1982. Fortunately 13 of them were soon back at work at Unger Fabrikker.

1982

Death of T.B. Unger

Retirement was not something T.B. Unger found easy, and even after relinquishing his post as chairman in 1982 he continued to participate in company affairs. In December he collapsed and died on his way home from a business lunch in Denmark. He was 87 and had devoted nearly 60 years of his life to the company.

1982

1983-1984

1983-1984

Borregaard take-over

The future ownership of the company had long been under discussion, since no one in T. B. Unger’s immediate family wished to take over. A number of different companies, in Norway and abroad, had shown interest, the most persistent of these being Borregaard in neighbouring Sarpsborg. In 1983 agreement on a take-over was reached, and effectuated the following year.

1984

Combining forces

The strategy behind the take-over was that the two units should combine forces to start. production of surfactants. Borregaard’s contribution would be in the fields of product development and laboratory work as well as finance and marketing. On March 19, 1984 a new board of directors was appointed with Tor G. Jacobsen as chairman. Halvard J. Kvisgaard became the new managing director.

1984

1985

1985

Short lived

Unger Fabrikker’s honeymoon with Borregaard was short-lived. In 1985 Borregaard merged with Orkla Grube-Aktieselskap and the company experienced a change of course. Consumer-orientated industry and, later, media and finance became Orkla’s chief interests, and some industrial companies in the group, among them Unger Fabrikker, found themselves up for sale.

Unger Fabrikker was now looking for a new buyer. Negotiations were begun with the Norwegian company Surfatech A/S, a subsidiary of Innovatech A/S, which specialized in chemical innovation particularly in the field of surfactants, and with the Canadian Alkaril Chemicals Limited.

Unger Fabrikker was now looking for a new buyer. Negotiations were begun with the Norwegian company Surfatech A/S, a subsidiary of Innovatech A/S, which specialized in chemical innovation particularly in the field of surfactants, and with the Canadian Alkaril Chemicals Limited.

September 1985

Barrels

On September 3, 1985 Unger Fabrikker seized the national headlines when environmentalist invaded the company’s plant at Nabbetorp, claiming that large amounts of dangerous chemicals were buried there. These claims were soon shown to be highly exaggerated and after a report from the Norwegian Pollution Control Authority charges were either dropped or dismissed.

September 1985

1987

1987

Rising from the ashes

On July 1, 1987 Orkla/Borregaard sold all its shares in Unger Fabrikker to Surfatech A/S, which were left “holding the baby” since the planned cooperation with Alkaril Chemicals Ltd and an international oil company never materialized. Three weeks later the company’s sulphonation plant burnt down. Fortunately, a new reactor enabling the production of first-class ether sulphates was already ordered and was installed soon afterwards.

The new owners’ commitment to developing the company was soon apparent. While one development project involving water purification technology proved difficult to sustain and was finally shelved after a 3-4 year period, large investments were made in the field of anionic surfactants, Unger’s core business, and proven successful.

The new owners’ commitment to developing the company was soon apparent. While one development project involving water purification technology proved difficult to sustain and was finally shelved after a 3-4 year period, large investments were made in the field of anionic surfactants, Unger’s core business, and proven successful.

Late 80's and early 90's

Road to investments

The late 80’s and early 90’s saw a number of development plans requiring significant investment. New drum driers were installed, and three neighbouring sites were purchased, facilitating the construction of a new roads for both heavy-transport and car access. The company’s new owners played an active role in arranging financial loans for these investments.

Late 80's and early 90's

1990 – 1992

1990 – 1992

Held by Thon

In 1990 Jan B. Bøler was appointed fulltime Managing Director, while his predecessor Halvard J. Kvisgaard became responsible for quality managment and procurement of raw materials. In 1992 Unger Fabrikker was transferred to Thon Holding AS. Roald Aukner became Chairman of the Board with Olav Thon, Halgrim Thon and Truls Holthe representing the owners and treasurer Kjell Børresen and Ragnar Kjelsaas as staff representatives.

2000 – 2004

Agreement on Inclusive Working Conditions

For a long period of time, Unger struggled with a high level of non-attendance due to sick leave and in 2002 Unger decided on an Agreement on inclusive Working Conditions. In the following years, sick leave was reduced from approx. 15% to 1,76% in 2004. In the same period of time, Unger also managed to turn negative results into a healthy profit.

2000 – 2004

2005 – 2008

2005 – 2008

All aboard!

"Quality at all levels" had become the mantra within business management and organizational development from the early 1980s. As we have already seen, Unger Fabrikker joined in on this development and in a larger perspective, both ISO-certification and the concept of an inclusive working life was a part of this philosophy.

In January 2005 Terje Kristiansen and Geir Karlsen travelled to Volvo Kompetansesenter in Sweden to attend the "Diplomutbildning for TPM". Total Productivity Management is a branch on "The Tree of Quality" and they conducted a 9-month long education attending 3- day sessions every month. Between every session, the students would do self-studies and solve assignments. The course also gave the students a thorough insight into how other companies work since classes took place in different locations in Sweden, Denmark and Norway. The overall idea was both simple and obvious: "All aboard". This was all about establishing a culture of increased value added in production at all times. The overall program was organizing practical systems to prevent loss and with a vision of zero mistakes, involving all functions, processes and coworkers.

Unger Fabrikker chose 5 focus areas: continuous improvements, operator maintenance, specialist maintenance, competence and visualization. The last 2 areas were important, especially the area of visualization. Amongst the employers at Unger, there was a great span of abilities and required skills, so this part of the educational program became the ultimate prerequisite for success. In the Autumn of 2005, the first Masterplan was presented to be realized by 2008.

In January 2005 Terje Kristiansen and Geir Karlsen travelled to Volvo Kompetansesenter in Sweden to attend the "Diplomutbildning for TPM". Total Productivity Management is a branch on "The Tree of Quality" and they conducted a 9-month long education attending 3- day sessions every month. Between every session, the students would do self-studies and solve assignments. The course also gave the students a thorough insight into how other companies work since classes took place in different locations in Sweden, Denmark and Norway. The overall idea was both simple and obvious: "All aboard". This was all about establishing a culture of increased value added in production at all times. The overall program was organizing practical systems to prevent loss and with a vision of zero mistakes, involving all functions, processes and coworkers.

Unger Fabrikker chose 5 focus areas: continuous improvements, operator maintenance, specialist maintenance, competence and visualization. The last 2 areas were important, especially the area of visualization. Amongst the employers at Unger, there was a great span of abilities and required skills, so this part of the educational program became the ultimate prerequisite for success. In the Autumn of 2005, the first Masterplan was presented to be realized by 2008.

2006

Change of Managing Director

The change of management always characterises a company. When Jan Birger Bøler retired in January of 2006 and Jan Ivar Ruud took over the Chief's chair, this was also a milestone in the history of Unger Fabrikker. The jazz loving Managing Director had held the position for 17 years, and looked back on this time concluding that “no days have been the same and that is the reason why I have never been bored working at Unger”.

Jan Birger Bøler left a company better equipped than ever before to meet the justified needs and demands from the employees, the Government and society in general.

Jan Ivar Ruud quickly settled into the Unger spirit, even though there is always a certain ambivalent welcoming when management changes. One of the real blue collar veterans had a necessary visit to the Administration floor, and after a meeting with HR Manager Ann-Karin Buskoven, they went out to the reception area and met Jan Ivar Ruud. “Oh, look” says Ann-Karin. “Let me introduce you to the new Managing Director”. They greeted each other and the veteran asked where Mr. Ruud lived upon which Ruud replied “Sarpsborg”. This caused a spontaneous response from the veteran “Great, as if things could not be any worse".

Jan Birger Bøler left a company better equipped than ever before to meet the justified needs and demands from the employees, the Government and society in general.

Jan Ivar Ruud quickly settled into the Unger spirit, even though there is always a certain ambivalent welcoming when management changes. One of the real blue collar veterans had a necessary visit to the Administration floor, and after a meeting with HR Manager Ann-Karin Buskoven, they went out to the reception area and met Jan Ivar Ruud. “Oh, look” says Ann-Karin. “Let me introduce you to the new Managing Director”. They greeted each other and the veteran asked where Mr. Ruud lived upon which Ruud replied “Sarpsborg”. This caused a spontaneous response from the veteran “Great, as if things could not be any worse".

2006

2012

2012

RSPO

Unger Fabrikker joined in as an RSPO member in 2012. The letters RSPO stands for “Round Table for Sustainable Palm Oil”. The Organization is established by the palm oil producers aiming to work for sustainability in production based on Palm Oil. In 2015, Unger was certified according to the RSPO requirements as the first in Scandinavia.

2020

Emission reduction

Until 2019, the continuos increase in production also led to an increase in the emission of greenhouse gasses. The reason being that all energy production was based on the use of oil. However, in 2020 the installation of an electric boiler contributed to a CO2 reduction of 3.400 tonnes. The transition to electrical trucks has nearly eliminated the annual use of diesel with 40.000 litres per year.

2020

2022

2022

Celebrating 100 years with a new building

In the 100- anniversary year at Unger, our laboratory is working with 286 different additives for cleaning products, soap, toothpaste and other hygiene products as well as a wide variety of products to be used in the construction industry, amongst other areas.

The smell of Sulphur was intense when the old Sulphur shack was demolished in autumn of 2021, and several unexpected surprises were uncovered in the ground, but finally the building process could start.

A grand new building has risen, welcoming all into the next 100 years of Unger history. The ground floor contains wardrobes for all employees as well as large and practical meeting rooms. The first floor is designed with offices for the Marketing department.

In this new building, an exhibition representing the company`s 100- year long history will be established. The new building is standing in the exact spot of one of the company`s oldest buildings testifying continuity and a belief in the future of Unger Fabrikker - It is a brand new “Welcome to Unger Fabrikker”!

The smell of Sulphur was intense when the old Sulphur shack was demolished in autumn of 2021, and several unexpected surprises were uncovered in the ground, but finally the building process could start.

A grand new building has risen, welcoming all into the next 100 years of Unger history. The ground floor contains wardrobes for all employees as well as large and practical meeting rooms. The first floor is designed with offices for the Marketing department.

In this new building, an exhibition representing the company`s 100- year long history will be established. The new building is standing in the exact spot of one of the company`s oldest buildings testifying continuity and a belief in the future of Unger Fabrikker - It is a brand new “Welcome to Unger Fabrikker”!

Career

Do you want to join our team in developing the future of sustainable products?

With the highest commitment to customer support and rapid service, we aim to be second to none in providing satisfaction for our customers.